JLR Drone Trial Cuts Inspection Time By 95%

Check out the Best Deals on Amazon for DJI Drones today!

JLR has rolled out an ambitious drone trial at its Electric Propulsion Manufacturing Centre in Wolverhampton, where the Elios 3 from Flyability sliced a four hour inspection routine down to ten minutes, a time collapse so extreme it feels almost cartoonish until you realize it is simply the inevitable direction of factory automation, as Jaguar Land Rover reported in a press release.

The drone reaches the high corners and narrow pockets of the facility while the maintenance team remains safely on the ground, which means no climbing platforms, no awkward balancing acts and no pauses in productivity while someone wrestles with equipment that belongs in a circus rather than a modern electric propulsion plant.

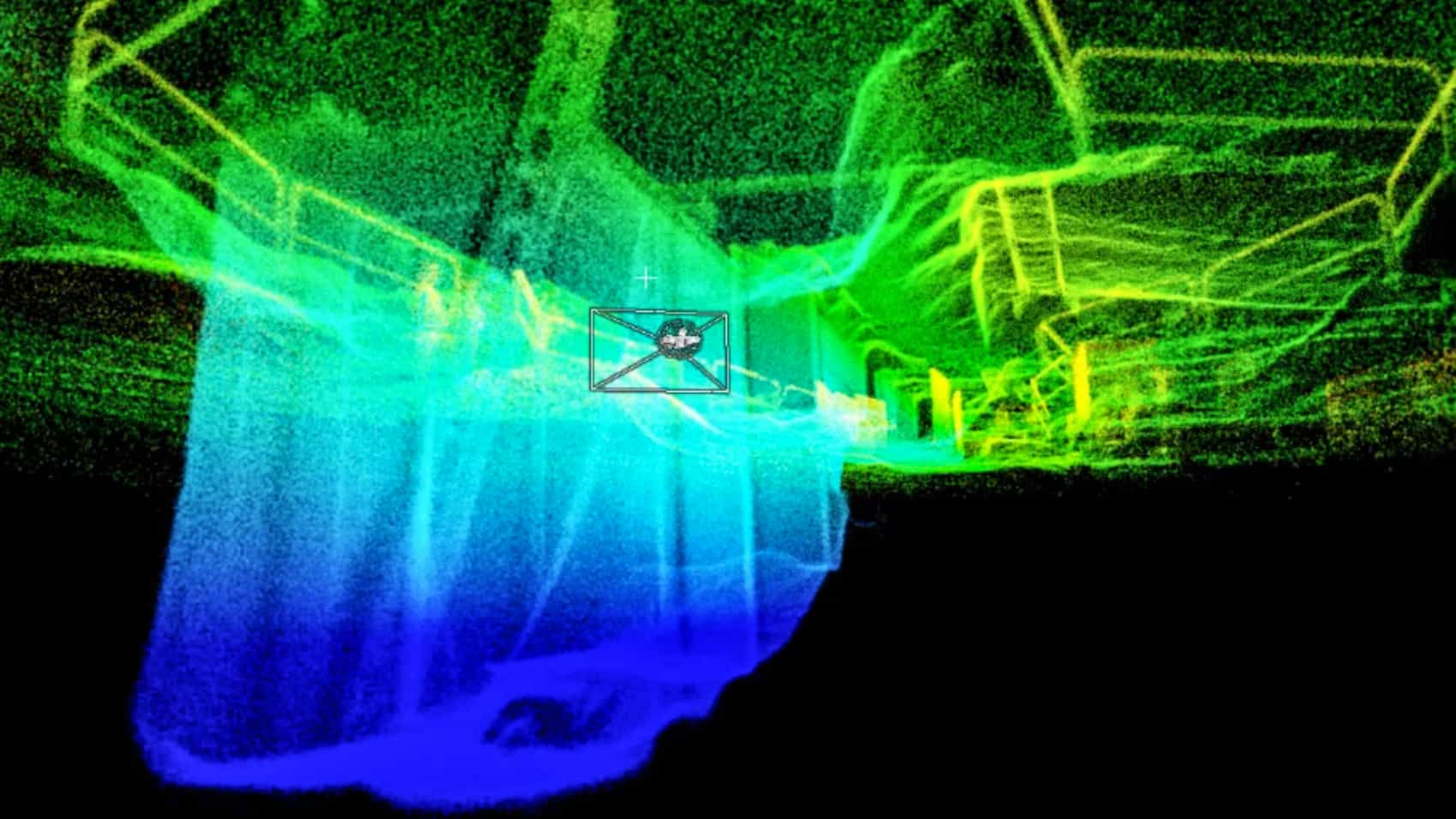

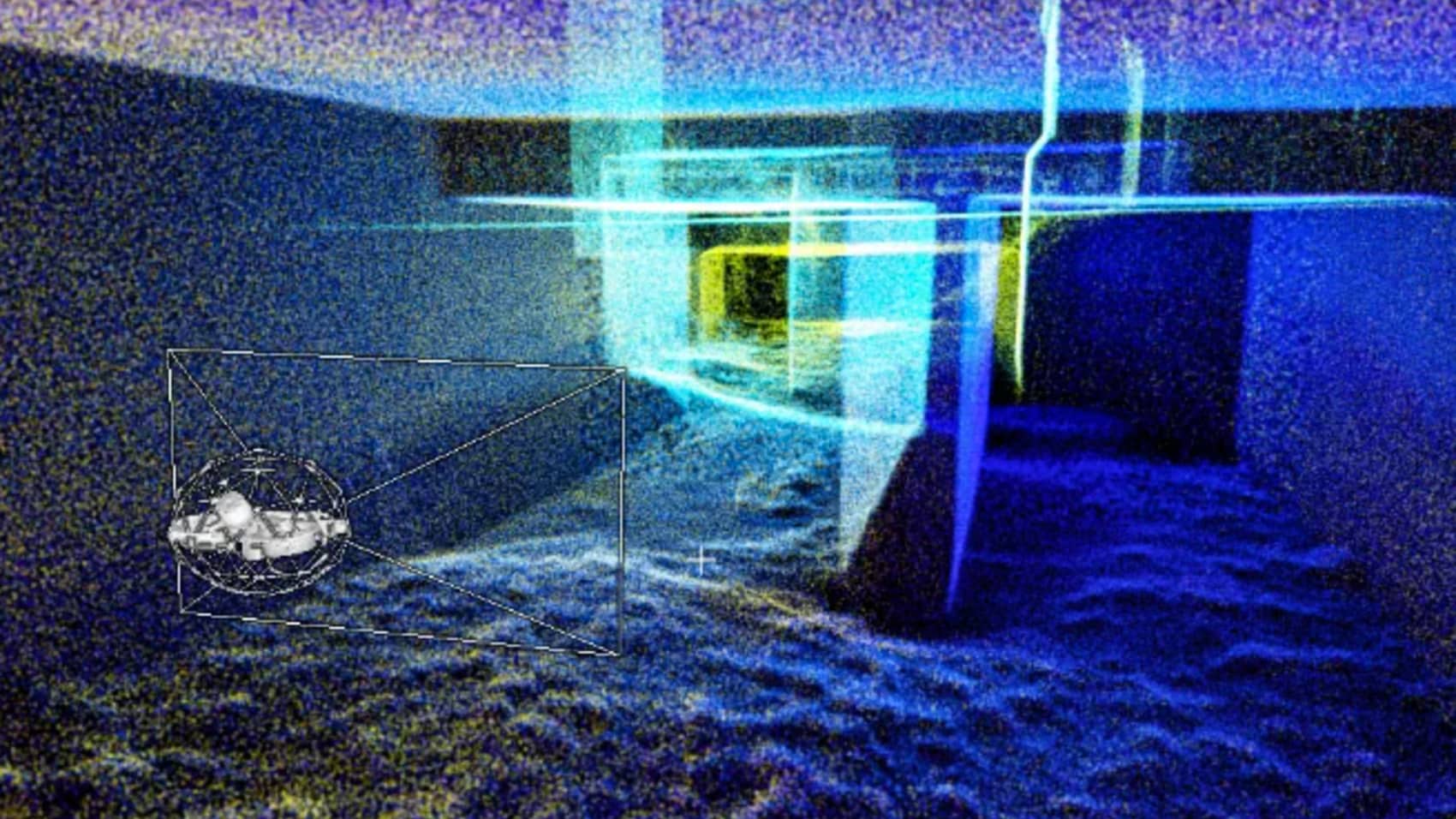

The craft streams a live 3D map through a tablet, giving teams a full view of machinery, rooftops, ducts and every other overlooked nook, which helps JLR prevent downtime before it can begin and frees human workers to focus on the tasks that actually move the company forward.

The drone even contributes to JLR’s Reimagine strategy and Future Skills Programme, quietly acting as an airborne tutor while employees learn digital tools and electrification tech that will define the next chapter of automotive manufacturing.

LiDAR Mapping, Thermal Insight And A Workforce Learning On The Fly

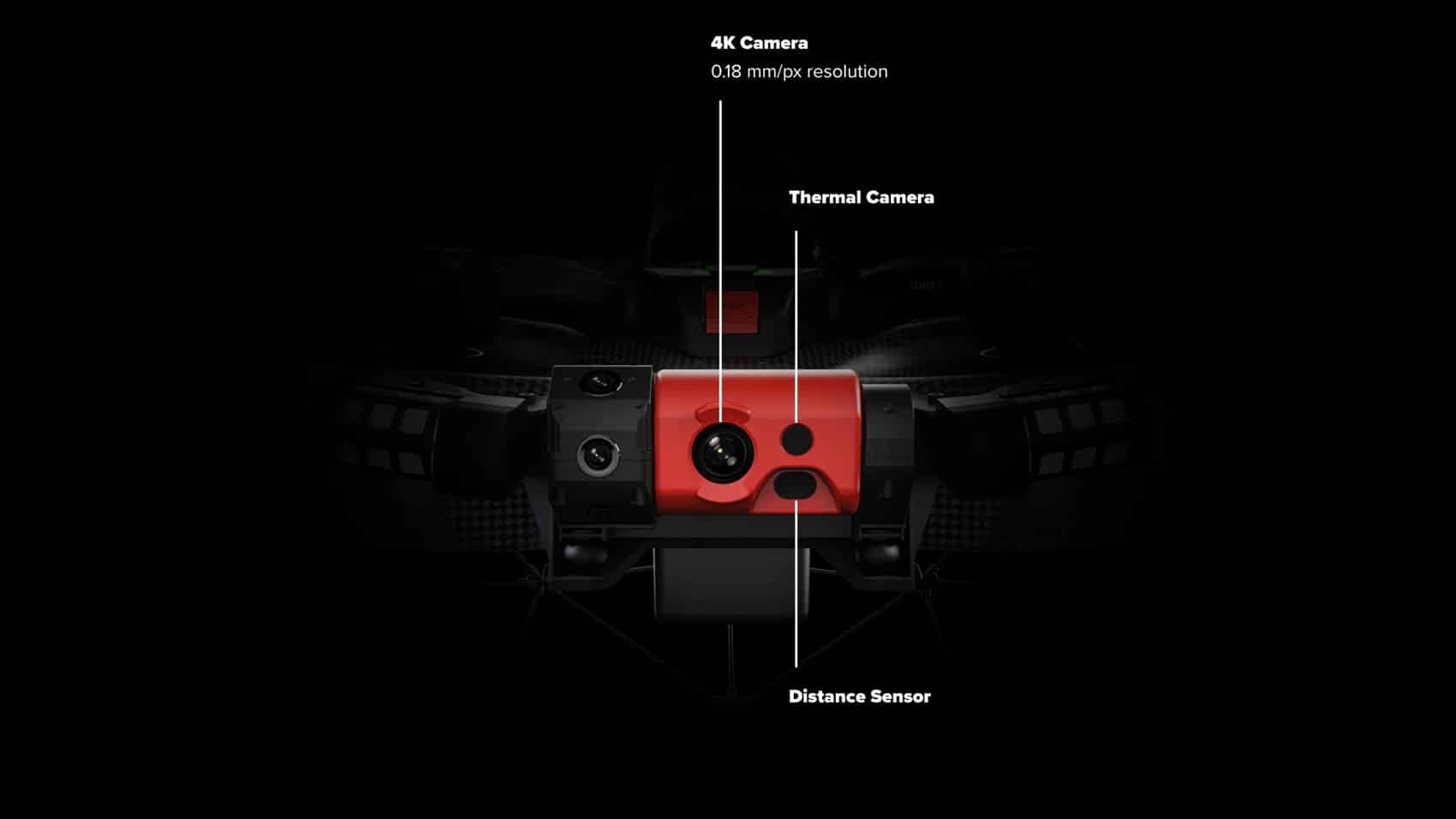

The Elios 3 uses LiDAR sensors (just like my gorgeous Neo 2) to bathe the environment in laser pulses that return with surgically precise distance data, stacking those measurements into a coherent 3D map that behaves like a living blueprint of the entire facility, a blueprint you can rotate, zoom, explore and interrogate.

A thermal camera rides along as the drone’s second set of eyes, exposing overheating components or insulation failures long before they show up as expensive problems on the financial sheet, and in doing so it quietly pushes JLR toward lower emissions and better energy efficiency.

Executive Director of Industrial Operations Nigel Blenkinsop described the trial as a catalyst for safer work, less downtime and stronger digital skills, while project engineer Shantnu Mehta confessed that she never expected drone piloting to land in her career path, yet she is now flying through industrial canyons with a sense of pride that comes from shaping the future rather than simply working inside it.

The trial also aligns with JLR’s broader industrial transformation effort, part of a much larger multibillion annual investment that includes factory modernization, new product development and innovation partnerships through the company’s Open Innovation programme.

Warehouse Inventory Is Next, With Automation Doing The Heavy Lifting

After proving itself in Wolverhampton, the drone heads to the Logistics Operations Centre in Solihull, a colossal warehouse the size of thirteen soccer pitches, where it will take on inventory checks that normally eat hours of human time and patience.

Barcode scanners will transform the drone into a floating auditor, moving shelf to shelf with more accuracy and far less grumbling than any exhausted employee armed with a clipboard, producing faster stock updates and cleaner data for teams managing space, flow and supply.

Manual stocktaking becomes automated verification, safety improves as workers spend less time wandering high storage racks and error rates shrink as the drone methodically scans everything it sees.

The move also supports JLR’s plan to train nearly thirty thousand employees in digital and electrification skills, which means the drone is not just a piece of hardware but a bridge into the workforce JLR wants to build for the decade ahead.

DroneXL’s Take

Industrial drones are slipping into factories with the quiet confidence of tools that know they are about to rewrite decades of slow and painfully manual processes, and JLR’s ninety five percent time reduction is exactly the kind of proof that forces every major manufacturer to rethink their workflows.

This is not some novelty gadget buzzing around for publicity, it is a serious productivity engine with real data, real insight and real impact. Expect the inventory phase in Solihull to deliver equally sharp gains, because once a drone can map your factory, scan your shelves and warn you about failures before they happen, the only logical move is to give it more responsibility and let it run.

Photo credit: Jaguar Land Rover, Flyability

Discover more from DroneXL.co

Subscribe to get the latest posts sent to your email.

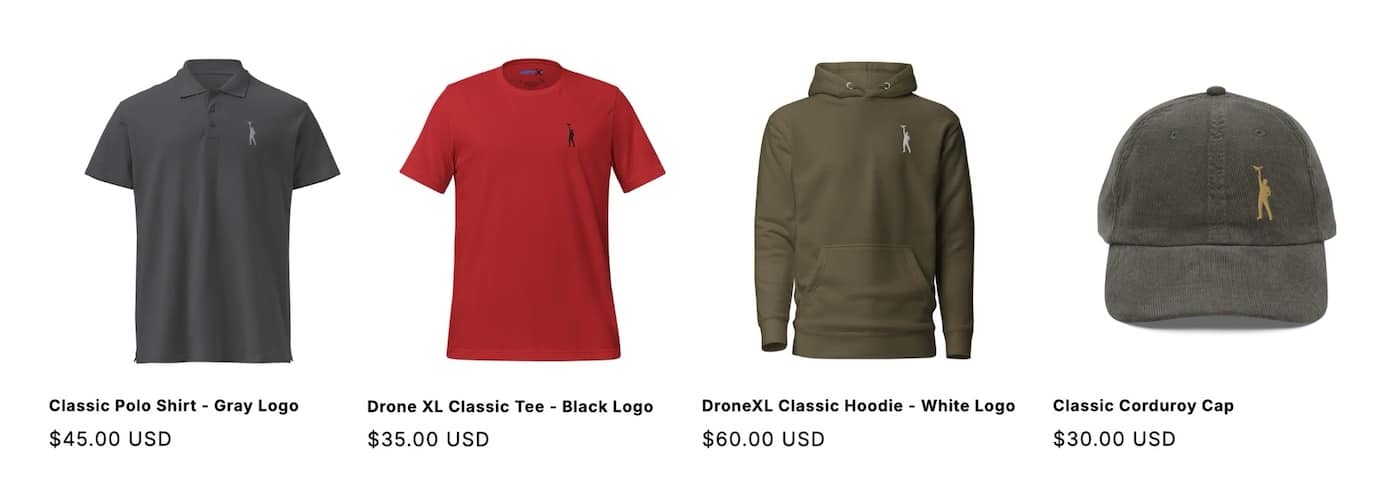

Check out our Classic Line of T-Shirts, Polos, Hoodies and more in our new store today!

MAKE YOUR VOICE HEARD

Proposed legislation threatens your ability to use drones for fun, work, and safety. The Drone Advocacy Alliance is fighting to ensure your voice is heard in these critical policy discussions.Join us and tell your elected officials to protect your right to fly.

Get your Part 107 Certificate

Pass the Part 107 test and take to the skies with the Pilot Institute. We have helped thousands of people become airplane and commercial drone pilots. Our courses are designed by industry experts to help you pass FAA tests and achieve your dreams.

Copyright © DroneXL.co 2026. All rights reserved. The content, images, and intellectual property on this website are protected by copyright law. Reproduction or distribution of any material without prior written permission from DroneXL.co is strictly prohibited. For permissions and inquiries, please contact us first. DroneXL.co is a proud partner of the Drone Advocacy Alliance. Be sure to check out DroneXL's sister site, EVXL.co, for all the latest news on electric vehicles.

FTC: DroneXL.co is an Amazon Associate and uses affiliate links that can generate income from qualifying purchases. We do not sell, share, rent out, or spam your email.