3D-Printed Battlefield Factories Aim to Transform US Drone Production

Check out the Best Deals on Amazon for DJI Drones today!

Firestorm Labs believes the United States can overcome its drone production gap by putting factories directly on the battlefield. Their expeditionary manufacturing system, called xCell, fits inside two expandable twenty foot ISO containers, as reported by Business Insider.

Each unit carries industrial HP Multi Jet Fusion printers and semi-automated assembly stations that can turn mission requirements into ready-to-fly drones within hours, not weeks. Setup takes less than a day, and the system runs either on grid power, generators, or battery arrays. Now this is a fast technology that you want on your side.

The Pentagon is pushing for hundreds of thousands of low-cost, US-built drones over the next two years, backed by one billion dollars in funding.

Firestorm is already part of that effort after winning a one hundred million dollar Air Force contract and securing forty seven million dollars in Series A funding from major venture and defense investors.

As small drones become dominant tools in modern conflict, especially in Ukraine, the ability to fabricate them at the point of need has become a strategic priority, and the USA knows that.

xCell is designed for global deployment without a depot and can operate even in contested environments. Satellite communications provide optional high-bandwidth connectivity.

The containers expand outward to create a climate-controlled workspace, and testing in arctic conditions has demonstrated that the system can function across extreme environments. Firestorm plans to position an xCell somewhere in the US Indo Pacific Command by early 2026.

Scalable Production and Three Mission-Ready Drone Designs

Firestorm says xCell can produce up to fifty Group 2 airframes, hundreds of Group 1 airframes, or thousands of quad frames per month.

The exclusive mobile integration of HP’s MJF printing technology delivers speeds far beyond traditional additive systems, which allows operators to print mission-specific parts, adapt designs on-site, and repair equipment without waiting for shipments. The system supports Firestorm’s own drones, government designs, and third-party components.

The company is building three drone models alongside the manufacturing units. The Tempest is a modular Group 2 or 3 system with an open architecture that lets operators reconfigure propulsion, payloads, and mission software in minutes.

Photo credit: Firestorm

It fits in a single man-portable case and launches in under ten minutes. Tempest carries ten pounds of payload, cruises between sixty five and one hundred fifty miles per hour, and can fly up to four hundred miles with endurance up to six hours.

The Hurricane, in advanced development, is a low-cost unmanned aircraft deployed from Common Launch Tubes on platforms such as the MQ-9 and AC-130.

Photo credit: Firestorm

It is built for high-tempo operations where units need to push many drones across multiple missions. Hurricane carries up to six pounds of payload, cruises at one hundred miles per hour, and offers about one hour of endurance.

El Niño, also in advanced development, is Firestorm’s miniature precision-guided system. It is hand-launchable, weighs under ten pounds, and is ready to fly in under thirty seconds.

Photo credit: Firestorm

El Niño offers organic precision fires and real-time ISR for small teams, with a thirty mile range, half hour endurance, and a dash speed over one hundred twenty miles per hour. Onboard autonomous target recognition and terminal guidance allow small units to operate without external support.

Cutting Cost and Simplifying Logistics

Firestorm argues that xCell reduces the heavy logistics tail associated with moving complete drone systems into theater. Feedstock materials are globally available, and units can build only what they need, whether it is a replacement airframe, a custom payload mount, or a complete drone.

Semi-automated workflows lower manpower requirements while enabling rapid production cycles. Retired Army Gen. Richard Clarke, who once managed supply chains across the force, says that Firestorm’s approach strengthens the logistics backbone that modern operations depend on.

The company believes future versions of xCell will produce far more than drones, including medical devices or prosthetics, creating a forward manufacturing capability that could reshape how militaries sustain operations. This would be a ultra win for logistics teams.

The long-term goal is a distributed network of battlefield factories turning raw material into mission-ready systems almost instantly, a shift that could redefine US drone strategy.

DroneXL’s Take

Firestorm’s mobile manufacturing concept is bold, scalable, and built for the era of mass-produced battlefield drones.

The ability to print and deploy aircraft within hours could give the United States a faster way to meet exploding demand, and while printed nylon airframes may raise questions, the speed and adaptability of the xCell system could outweigh those concerns in many missions. If the Pentagon embraces this shift, edge manufacturing may become a core part of how the US stays competitive in the global drone race.

Photo credit: Firestorm

Discover more from DroneXL.co

Subscribe to get the latest posts sent to your email.

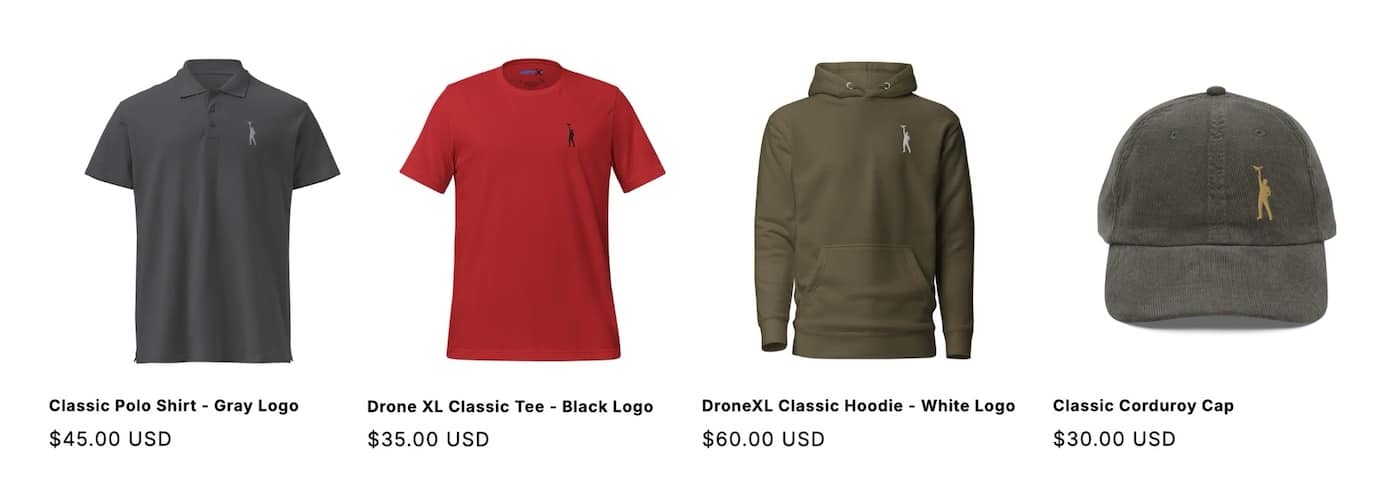

Check out our Classic Line of T-Shirts, Polos, Hoodies and more in our new store today!

MAKE YOUR VOICE HEARD

Proposed legislation threatens your ability to use drones for fun, work, and safety. The Drone Advocacy Alliance is fighting to ensure your voice is heard in these critical policy discussions.Join us and tell your elected officials to protect your right to fly.

Get your Part 107 Certificate

Pass the Part 107 test and take to the skies with the Pilot Institute. We have helped thousands of people become airplane and commercial drone pilots. Our courses are designed by industry experts to help you pass FAA tests and achieve your dreams.

Copyright © DroneXL.co 2026. All rights reserved. The content, images, and intellectual property on this website are protected by copyright law. Reproduction or distribution of any material without prior written permission from DroneXL.co is strictly prohibited. For permissions and inquiries, please contact us first. DroneXL.co is a proud partner of the Drone Advocacy Alliance. Be sure to check out DroneXL's sister site, EVXL.co, for all the latest news on electric vehicles.

FTC: DroneXL.co is an Amazon Associate and uses affiliate links that can generate income from qualifying purchases. We do not sell, share, rent out, or spam your email.