DJI Releases Mining Automation White Paper With Australian Case Studies Showing 60% Efficiency Gains

Check out the Best Deals on Amazon for DJI Drones today!

DJI Enterprise has published a comprehensive white paper providing mining operations with a practical roadmap for transitioning from manual drone flights to fully automated Beyond Visual Line of Sight workflows using DJI Dock systems. The guide features real-world case studies from Australian mining operations that demonstrate dramatic productivity improvements and enhanced worker safety.

The timing proves significant as the global mining industry continues its push toward automation and remote operations. With mining revenues exceeding $3 trillion in 2023, operations worldwide are seeking ways to improve efficiency while reducing risk to personnel in inherently hazardous environments.

Dramatic Efficiency Gains in Real-World Operations

DJI’s white paper documents specific productivity metrics from Australian mining deployments. Tests found that the time required to capture and process a post-blast photogrammetry survey dropped from 1.2 hours to just 30 minutes when using automated DJI Dock workflows compared to manual drone operations.

The efficiency improvements extend beyond flight operations. With a single DJI Dock system, remote pilots working eight-hour shifts can perform approximately 150-200 flights per month, totaling up to 50 flight hours. Automated ground control point markings delivered even more dramatic results, saving up to 94% of time in data processing workflows.

The white paper explains how these improvements stem from eliminating travel time to inspection sites, reducing on-site staffing requirements for drone pilots, and streamlining photogrammetry processing tasks through automation and integration with existing software platforms.

Australian Mining Operations Prove Dock Reliability in Extreme Conditions

The white paper features two detailed case studies from Australian mining operations that tested DJI Dock systems under demanding real-world conditions. At Rio Tinto’s Gudai-Darri iron ore mine in the Pilbara region, automated drone operations demonstrated resilience in extreme heat reaching 50°C (122°F), pervasive magnetic red dust, and cyclone-prone weather patterns.

Gudai-Darri represents Rio Tinto’s most technologically advanced mine, already operating fleets of autonomous haul trucks, drills, water carts, and heavy-haul trains monitored remotely from Perth over 1,500 kilometers (932 miles) away. The DJI Dock deployment enabled data-driven decision-making through remotely monitored flights and automatic recharging, improving both worker safety and operational efficiency.

At Paddington Operations near Kalgoorlie in Western Australia’s goldfields, the DJI Dock conducted aerial surveys of post-blast muckpiles. Using AI-driven modeling, operators improved grade control, reduced ore dilution, and lowered processing costs by identifying higher-quality ore for the processing plant. The operation is owned by Norton Gold Fields and centers around a 3.73 million tonne per annum capacity processing mill.

Navigating Complex BVLOS Regulatory Requirements

A significant portion of DJI’s white paper addresses regulatory navigation and operational infrastructure requirements for scaling automated BVLOS operations. The guide covers licensing pathways including Remote Pilot License requirements, BVLOS approvals, Outside Controlled Airspace operations, Instrument Rating Examination qualifications, and Specific Operation Risk Assessment based BVLOS approvals.

The document also details Remote Operating Centre certification requirements and Human-Machine Interface design considerations. Essential operational processes receive attention including redundancy and fatigue management protocols, emergency drill procedures, and stakeholder engagement strategies for operations in complex airspace.

DJI’s focus on Australian regulatory frameworks reflects the country’s progressive approach to BVLOS approvals. Australia’s Civil Aviation Safety Authority has implemented frameworks that allow qualified operators to self-assess locations for BVLOS operations rather than waiting months for individual site approvals.

Enhanced Safety Through Remote Operations

Mine sites present inherent hazards including large mobile machinery, open voids, blasting activities, and exposure to harsh environmental conditions. The white paper emphasizes how automated workflows enable operators to conduct more frequent inspections while working safely at Remote Operations Centers away from pit faces, blast zones, tailing facilities, and hypersaline pipelines.

Operationally, blast movements can be analyzed quickly for safer restart procedures using automated workflows. Repeatable surveys and inspections can be performed more frequently than manual operations allowed. When paired with intelligent analysis and automated alerts, operators can ensure assets and pipelines remain in working condition, environmental compliance requirements are met after weather events, and infrastructure development progresses according to plan.

The automated approach also enables trigger-based data captures using If This Then That logic for processing and reporting when changes or specific objects are detected, creating more responsive monitoring systems.

Implementation Roadmap for End-to-End Automation

DJI’s white paper provides detailed guidance for implementing end-to-end automated mining workflows built on the DJI Dock hardware platform and FlightHub 2 flight control software. The guide explains how operators can use DJI Dock to plan missions remotely, schedule flights in advance, and pilot docked drones on-demand when situations require immediate aerial perspective.

The document includes step-by-step breakdowns for automating data processing with existing photogrammetry software platforms. Examples include conducting automated volumetric measurements of ore stockpile inventory using geotechnical models, standardizing data capture protocols across multiple sites, and creating consistent reporting frameworks.

For mining operations considering the transition to automated workflows, the white paper serves as both a technical guide and a business case study demonstrating measurable returns on investment through reduced labor costs, increased flight frequency, faster data processing, and improved safety outcomes.

DroneXL’s Take

The release of this white paper represents a maturation point for DJI’s Dock platform in one of the most demanding commercial applications imaginable. When we first covered the DJI Dock 2 release in March 2024, the system was still largely theoretical for many industries. Now we’re seeing mining operations provide hard ROI data: 60% reduction in survey time, 94% savings in data processing, and 150-200 monthly flights from a single dock.

The Australian case studies prove particularly relevant given the stark regulatory contrast between Australia and the United States. While Australian mining operations deploy BVLOS self-assessment frameworks that reduce approval timelines from months to days, U.S. operators continue navigating proposed Part 108 rules that industry groups warn could eliminate existing waiver pathways.

The Rio Tinto Gudai-Darri deployment builds on work we covered earlier this year when RocketDNA deployed their xBot system to the same mine. That deployment demonstrated BVLOS viability in extreme Pilbara conditions. This new white paper takes the next step by providing other mining operations with a replicable implementation framework.

Mining has always been ahead of other industries in embracing automation for safety and efficiency reasons. The progression from the original DJI Dock with the Matrice 30 to the refined Dock 2 system, and now to the recently launched Dock 3 platform, shows rapid iteration driven by real-world feedback from demanding users like mining operations.

The question for other industries: if automated BVLOS workflows can survive 50°C heat, magnetic dust, and cyclone winds while delivering measurable efficiency gains, what’s stopping broader adoption in less extreme environments? The answer increasingly appears to be regulatory frameworks rather than technological limitations.

What do you think about automated mining drone workflows? Share your thoughts in the comments below.

Discover more from DroneXL.co

Subscribe to get the latest posts sent to your email.

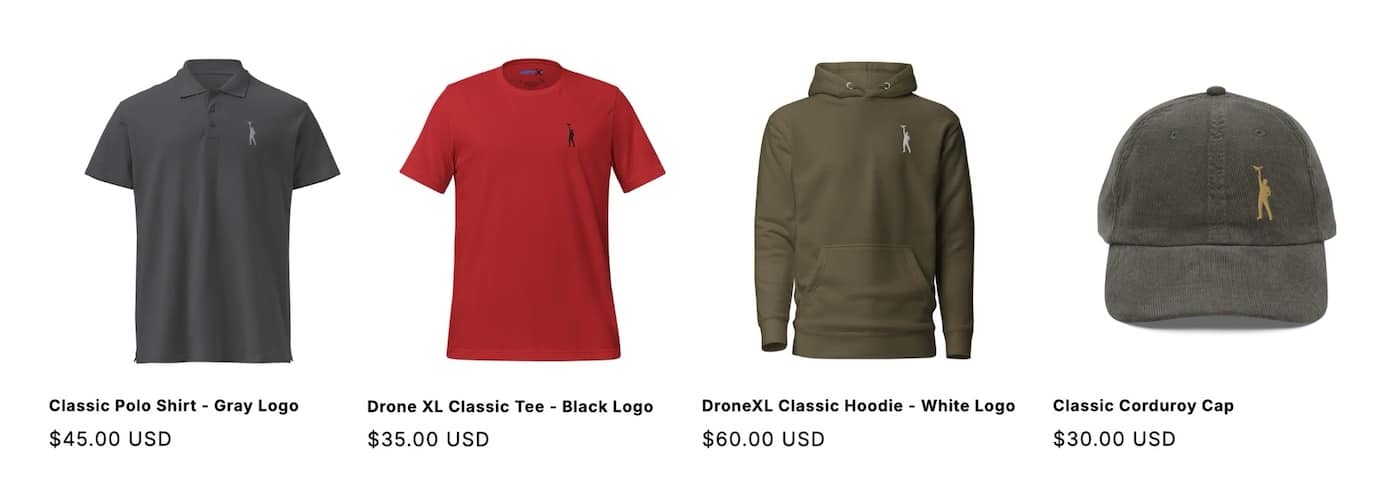

Check out our Classic Line of T-Shirts, Polos, Hoodies and more in our new store today!

MAKE YOUR VOICE HEARD

Proposed legislation threatens your ability to use drones for fun, work, and safety. The Drone Advocacy Alliance is fighting to ensure your voice is heard in these critical policy discussions.Join us and tell your elected officials to protect your right to fly.

Get your Part 107 Certificate

Pass the Part 107 test and take to the skies with the Pilot Institute. We have helped thousands of people become airplane and commercial drone pilots. Our courses are designed by industry experts to help you pass FAA tests and achieve your dreams.

Copyright © DroneXL.co 2026. All rights reserved. The content, images, and intellectual property on this website are protected by copyright law. Reproduction or distribution of any material without prior written permission from DroneXL.co is strictly prohibited. For permissions and inquiries, please contact us first. DroneXL.co is a proud partner of the Drone Advocacy Alliance. Be sure to check out DroneXL's sister site, EVXL.co, for all the latest news on electric vehicles.

FTC: DroneXL.co is an Amazon Associate and uses affiliate links that can generate income from qualifying purchases. We do not sell, share, rent out, or spam your email.